Decarbonization

Toward a Sustainable Future

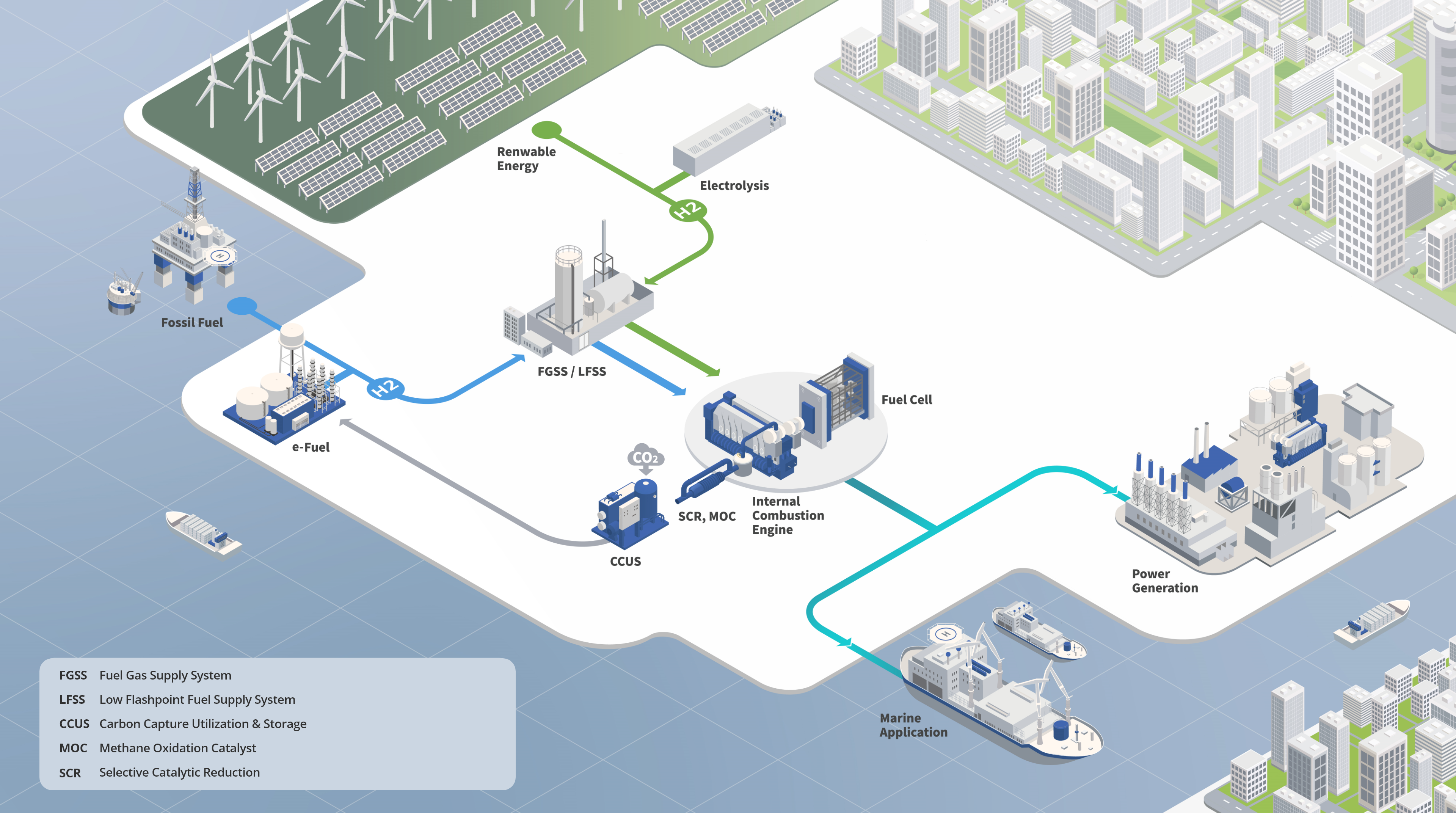

Our journey for carbon-neutral from reducing emission to zero-emission

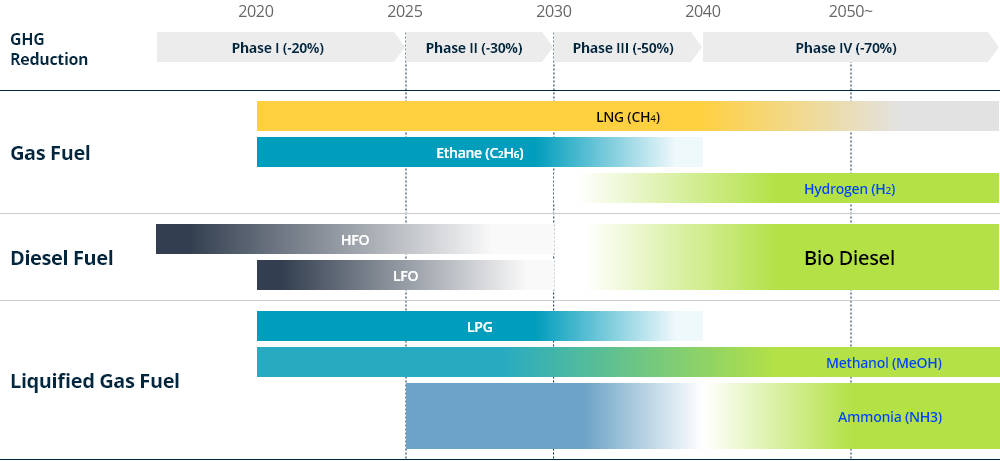

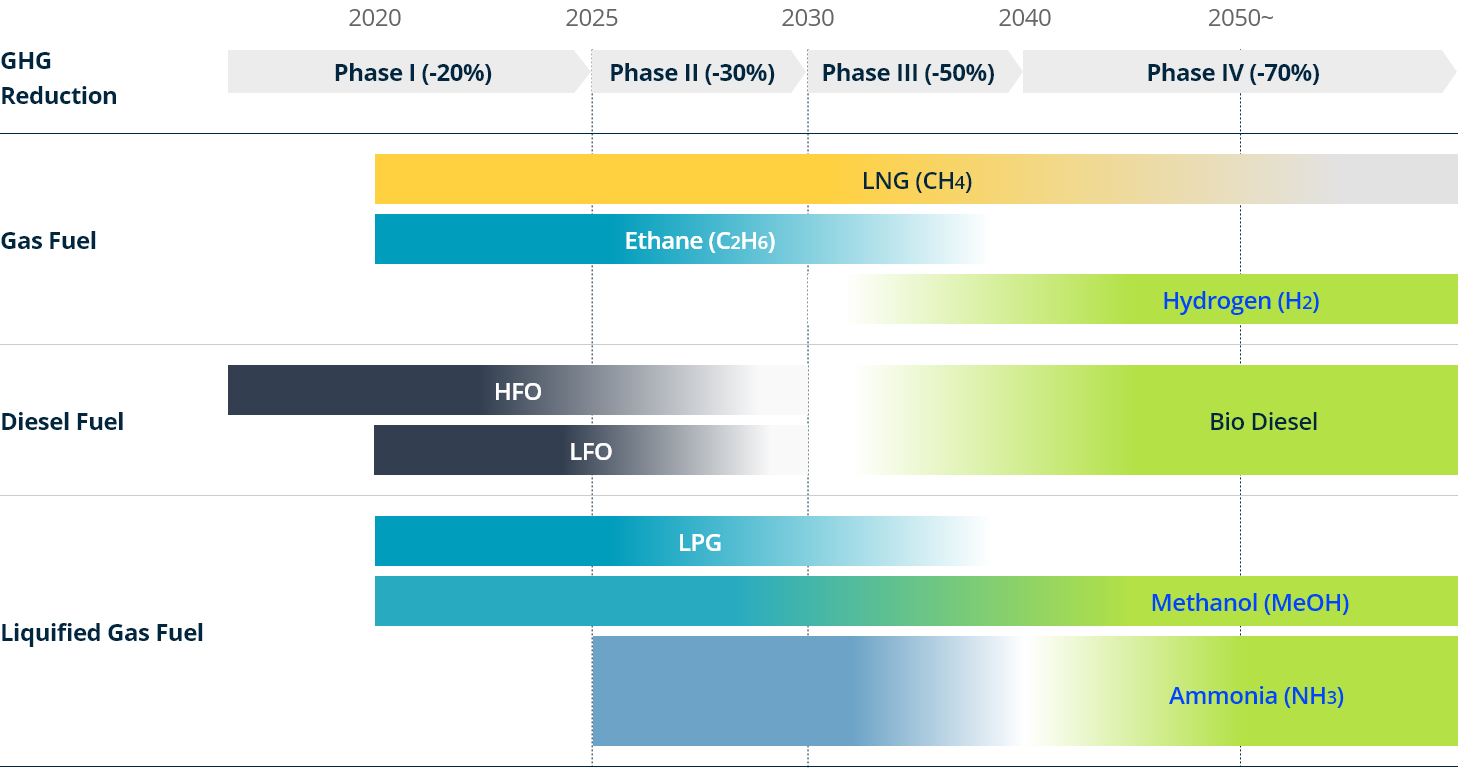

HHI-EMD is developing various technologies to respond to global warming and environmental regulations.

To reduce

CO₂, we developed a Gas/DF engine using natural gas, a low-carbon fuel and a hybrid propulsion

system. Furthermore,

we are making efforts to develop engines that use eco-friendly fuels such as

methanol, ammonia, and hydrogen for the

future.

Future

for Decarbonization

for Decarbonization

We respond on the global climate change and its many negative impacts. All options regarding possible sources of power, such as electrification, hybridization, and alternative fuels (including hydrogen, biofuels, and others) are being considered in our research. The resesarch also includes developing engines that are capable of running on both carbon-based and zero-carbon fuels in existing fleets.

HHI-EMD’s Alternative Fuel Development Research Progress

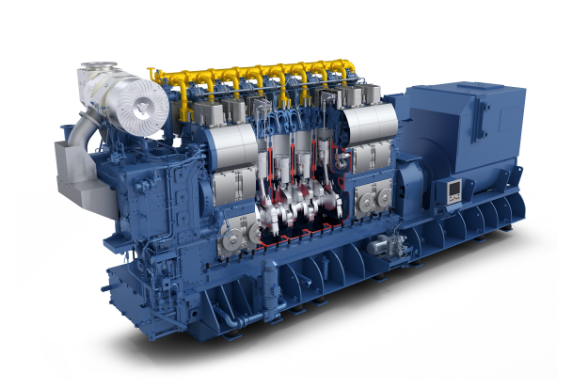

| HiMSEN Engine |

Diesel

Diesel

|

LNG

LNG

|

LPG

LPG

|

Bio Fuel(Liquid)

Bio Fuel(Liquid)

|

Ammonia

Ammonia

|

Methanol

Methanol

|

Hydrogen

Hydrogen

|

|---|---|---|---|---|---|---|---|

| Diesel | Ready | Ready | |||||

| LPDF | Ready | Under Development | Ready | Under Development | Under Development | Under Development | |

| HPDF | Ready | Under Development | Under Development | Under Development | Under Development | Under Development | |

| Gas(Spark) | Under Development | Ready |

Higher Efficiency,

Less CO₂

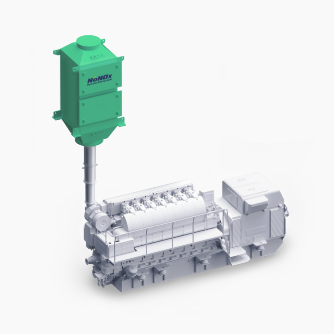

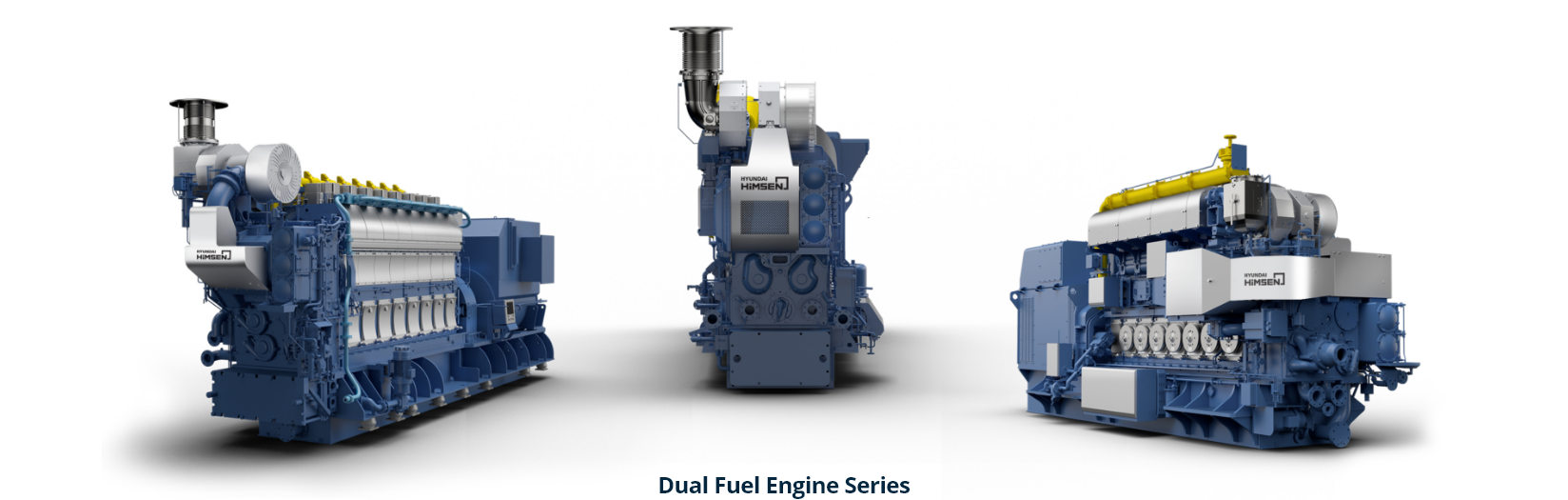

Multi Fuel Engine

Gas-fueled engines can reduce carbon dioxide emissions by 25% compared to diesel fuel. The combustion efficiency was improved to dramatically reduce methane emissions by applying several technologies such as MSS (Methane Slip Solution) and CCO (Cylinder Cut Off), GHG emission regulations to be strengthened in the future. With the engines used eco-friendly fuels such as methanol, ammonia and hydrogen, there is no problem.

-

25%Gas Fuel

-

40%FSM

-

~60%MSS

-

~80%CCO

-

- FSM (Fuel Sharing Mode)

- Reduced CO₂ by improving engine applicability of low-quality gas

-

- MSS (Methane Slip Solution)

- Partial load CH₄ reduction by improving combustion efficiency by truncation operation

-

- CCO (Cylinder Cut Off)

- Reduced CH₄ by reducing partial load unburned gas by multi-stage injection

-

- Carbon - Free Fuel

- Eco-friendly engine with no GHG emissions

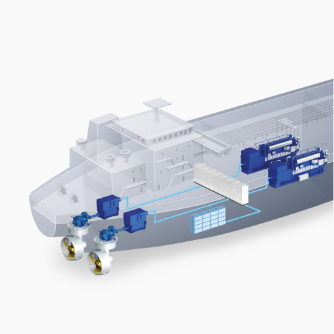

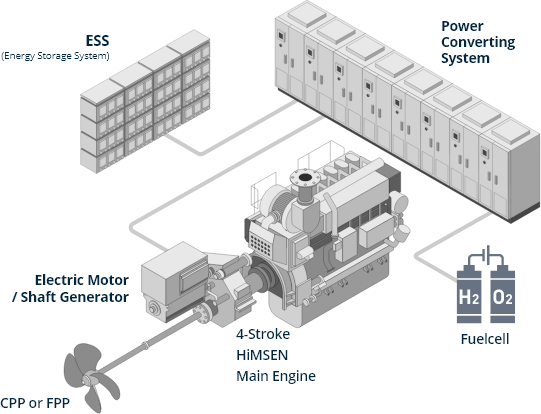

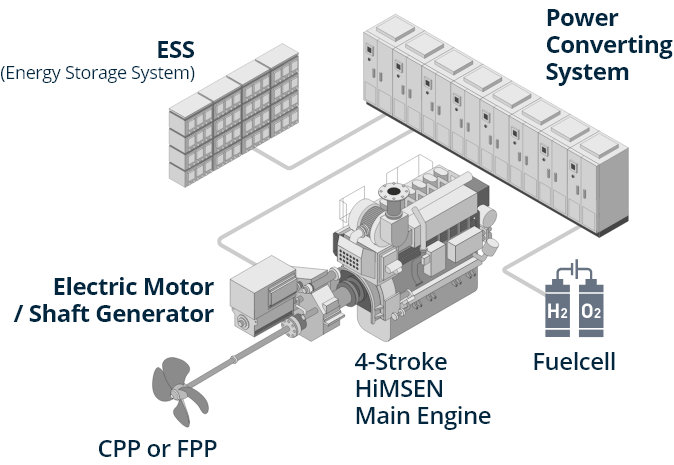

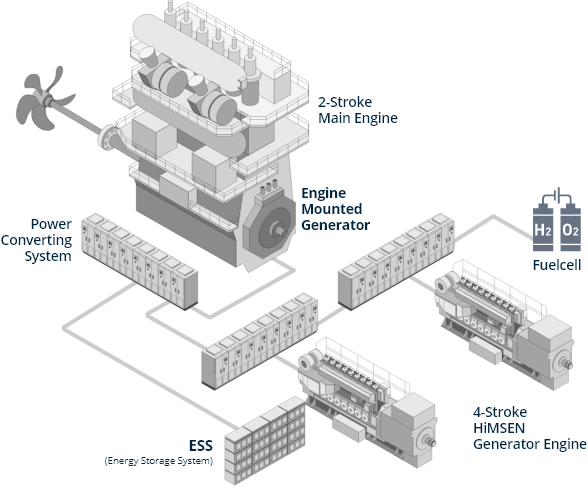

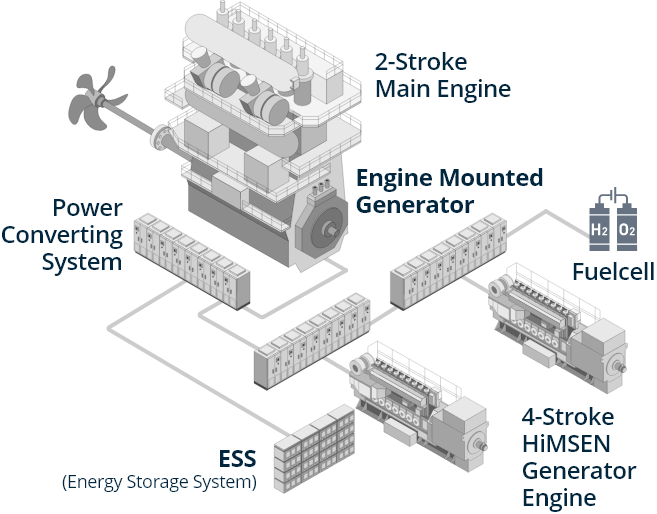

Hybrid Propulsion System

Hyundai Heavy Industries has launched a program called the HiMSEN Hybrid Propulsion System.

Its goals include minimizing fuel oil consumption and GHG emissions by means of variable

speed

operations, the strategic sizing of operating components, and optimized operational

modes.

- Up to zero Emissions

- High Performance,

Enhanced Efficiency - Reduced

Ownership Costs - Flexible Integration

of Equipment

CO₂-Neutral

Future of Energy

Applying Products

News

view more-

COMMON

“HD Hyundai Heavy Industries” wins iF Design Award 2025, internationally recognized for design excellence

03.10.2025 -

COMMON

Signed MOU with KEPCO for 'Carbon-free Distributed Generation Development and Business Cooperation'

02.11.2025 -

COMMON

Engine & Machinery Holds Customer Invitation Event 'HiMSEN Day'

10.30.2024 -

COMMON

HD Hyundai Heavy Industries Develops Ammonia Dual-Fuel Engine and Receives Approval from 7 Major Classification Societies

10.11.2024